Uprights

Our uprights are engineered to meet the highest standards, with options available to suit a wide range of industrial storage needs. From warehouse expansions to complete facility redesigns, Culver Equipment’s uprights are designed to seamlessly integrate with the rest of your pallet racking components. Paired with our expert pallet rack design and installation services, our uprights ensure that your storage system is both robust and adaptable.

Description

Uprights: The Backbone of Your Pallet Racking System

At Culver Equipment, we understand that the foundation of any reliable warehouse pallet rack system starts with strong and durable uprights. These vertical columns form the backbone of your racking system, providing the necessary support to handle heavy loads and ensuring the stability of your entire storage solution. Whether you’re implementing a simple selective pallet rack or a more complex system like drive-in pallet racks or pallet flow racks, the quality of your uprights is critical to the performance and safety of your warehouse.

Our uprights are engineered to meet the highest standards, with options available to suit a wide range of industrial storage needs. From warehouse expansions to complete facility redesigns, Culver Equipment’s uprights are designed to seamlessly integrate with the rest of your pallet racking components. Paired with our expert pallet rack design and installation services, our uprights ensure that your storage system is both robust and adaptable.

By choosing Culver Equipment for your pallet racking needs, you’re investing in the longevity and efficiency of your warehouse operations. Explore our full range of pallet rack accessories and safety features, including post protectors, end of aisle guards, and row spacers, to create a comprehensive racking solution that enhances both safety and storage capacity.

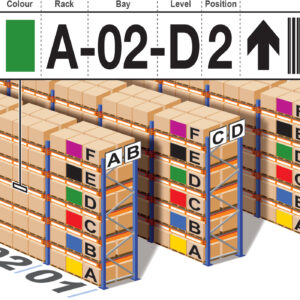

Key Components of Our Pallet Rack Systems:

- Uprights: The vertical columns that form the backbone of your pallet racking system, providing the necessary support for heavy loads.

- Post Protectors: Essential safety components that bolt on or are placed in front of uprights to safeguard the columns from impact, reducing the risk of damage.

- End of Aisle Guards: Protective barriers that go at the end of each aisle to shield the side of the frame from impact, ensuring the longevity and safety of your racking system.

- Anchors: Secure your pallet racks to the warehouse floor, providing stability and preventing accidental displacement.

- Row Spacers: These are crucial for maintaining proper spacing between back-to-back racks, often required by city or fire codes to allow adequate flue spacing.

- Beams: Horizontal elements that connect uprights and support the weight of your pallets, forming the levels of your racking system.

- J Pins: Safety pins that go into beams to help prevent them from dislodging, ensuring that your pallets stay securely in place.

- Fasteners: Various nuts, bolts, and other hardware that ensure all components of your racking system are tightly and securely connected.