Fasteners

Our fasteners are designed for durability and strength, providing reliable connections that enhance the stability of your racking system. Whether you’re assembling a new racking setup or reinforcing an existing one, the right fasteners are crucial to maintaining the integrity and safety of your storage solution.

Description

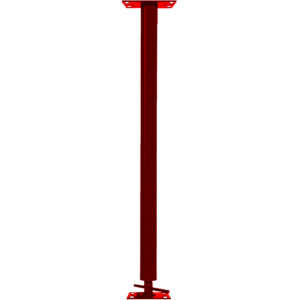

Fasteners: The Connective Hardware of Your Pallet Racking System

Fasteners are the unsung heroes of any warehouse pallet racking system, holding together the various components such as uprights, beams, and post protectors. At Culver Equipment, we provide high-quality fasteners that ensure all parts of your racking system are securely connected and capable of withstanding the demands of industrial storage.

Our fasteners are designed for durability and strength, providing reliable connections that enhance the stability of your racking system. Whether you’re assembling a new racking setup or reinforcing an existing one, the right fasteners are crucial to maintaining the integrity and safety of your storage solution.

Paired with other essential components like J pins, anchors, and row spacers, our fasteners help create a cohesive and robust pallet rack system that can handle heavy loads and withstand the rigors of daily warehouse operations. Culver Equipment’s expertise in pallet rack installation ensures that every part of your racking system is securely fastened and ready to perform at its best.

Key Components of Our Pallet Rack Systems:

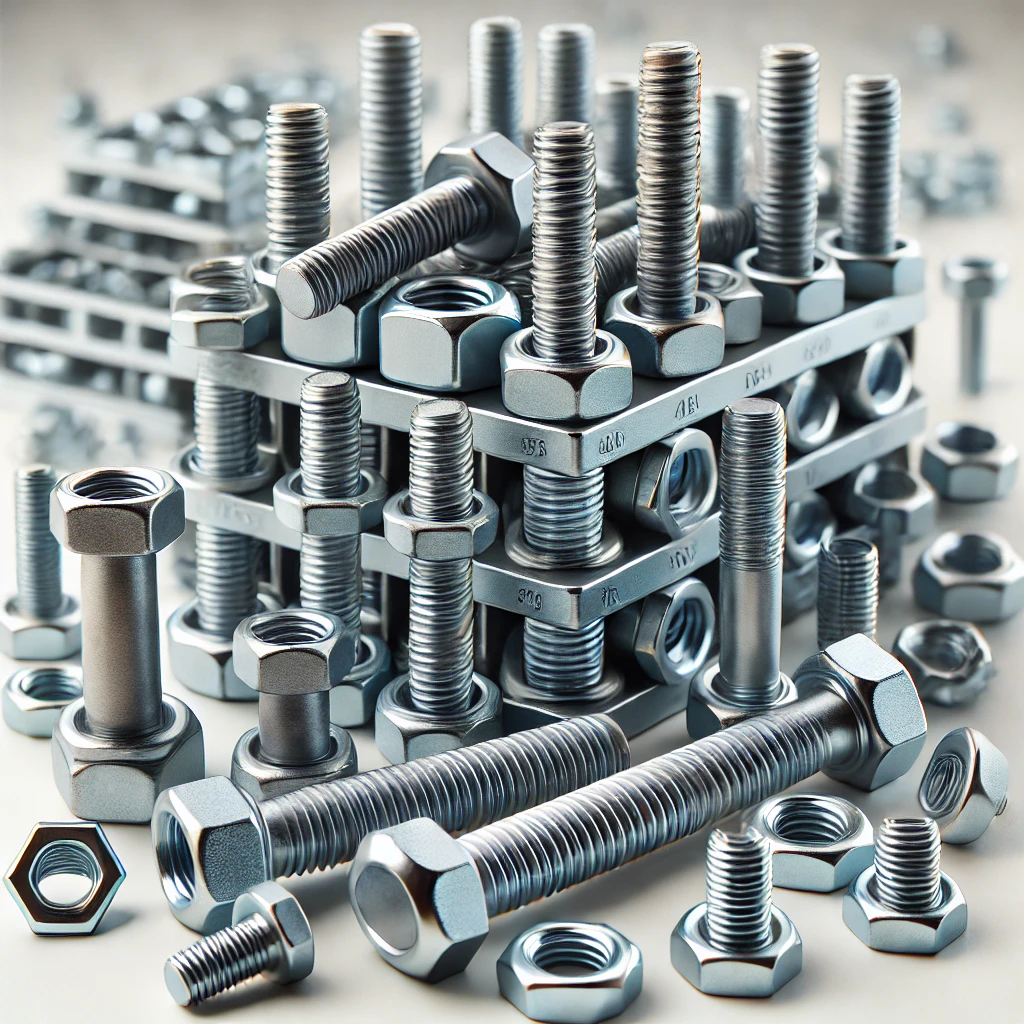

- Uprights: The vertical columns that form the backbone of your pallet racking system, providing the necessary support for heavy loads.

- Post Protectors: Essential safety components that bolt on or are placed in front of uprights to safeguard the columns from impact, reducing the risk of damage.

- End of Aisle Guards: Protective barriers that go at the end of each aisle to shield the side of the frame from impact, ensuring the longevity and safety of your racking system.

- Anchors: Secure your pallet racks to the warehouse floor, providing stability and preventing accidental displacement.

- Row Spacers: These are crucial for maintaining proper spacing between back-to-back racks, often required by city or fire codes to allow adequate flue spacing.

- Beams: Horizontal elements that connect uprights and support the weight of your pallets, forming the levels of your racking system.

- J Pins: Safety pins that go into beams to help prevent them from dislodging, ensuring that your pallets stay securely in place.

- Fasteners: Various nuts, bolts, and other hardware that ensure all components of your racking system are tightly and securely connected.