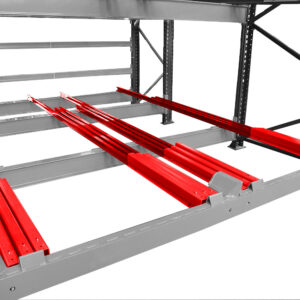

Drive-In Rails

Ideal for large quantities of similar products, drive-in rails help streamline loading and unloading processes by utilizing a first-in, last-out (FILO) system. These rails are critical components of drive-in racking, offering the strength and durability needed for long-term use in busy warehouse environments. Available in various sizes and configurations, our drive-in rails can be customized to fit your storage needs, ensuring that your warehouse can handle large volumes of inventory efficiently and safely.

Description

At Culver Equipment, our drive-in rails are designed to support efficient high-density storage solutions for warehouses and distribution centers. Drive-in racking systems allow forklifts to drive directly into the storage lanes, maximizing available space by eliminating the need for aisles. Our drive-in rails are built from heavy-duty steel and are designed to support the weight of pallets while guiding forklifts in and out of the racking system.

Ideal for large quantities of similar products, drive-in rails help streamline loading and unloading processes by utilizing a first-in, last-out (FILO) system. These rails are critical components of drive-in racking, offering the strength and durability needed for long-term use in busy warehouse environments. Available in various sizes and configurations, our drive-in rails can be customized to fit your storage needs, ensuring that your warehouse can handle large volumes of inventory efficiently and safely.

With drive-in rails, you can significantly increase storage capacity while reducing your warehouse footprint. Combined with drive-in uprights and other racking components, our rails provide a stable and reliable solution for high-density storage systems.

Explore our range of drive-in rails today and enhance your warehouse storage capabilities with this space-saving solution.